1. Working principle and characteristics of submerged burner

The immersion combustion method, also known as the liquid combustion method, is a new combustion technology. It is to fully mix gas and air, send it into the combustion chamber for complete combustion, and then spray high-temperature flue gas into the liquid to heat the liquid. Most of the combustion process of submerged combustion method belongs to complete premixed combustion, and its heat transfer process belongs to direct contact heat and mass transfer.

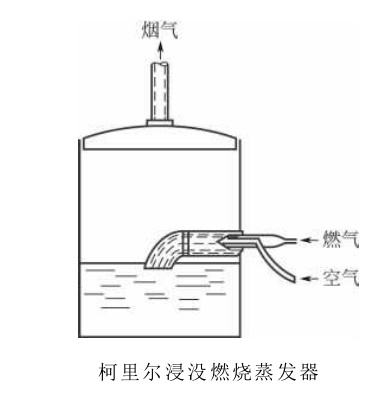

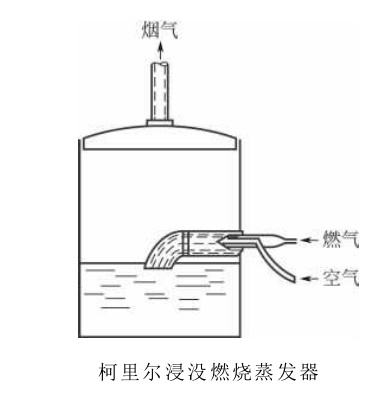

The earliest submerged combustion device was invented by Collier in England in 1889. Because the device does not have a special combustion chamber, it is directly sprayed into the liquid like a flame, so it is named submerged combustion (as shown in the figure below).

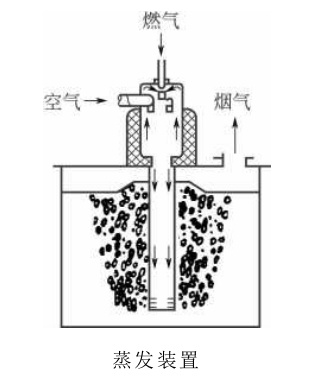

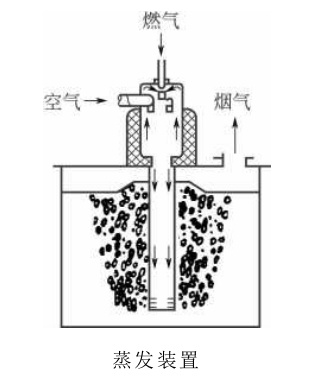

At present, the widely used submerged combustion device is the evaporation device shown in the figure below. Its main feature is that a combustion chamber is set on the liquid surface, which plays a role in ensuring stable flame and complete combustion.

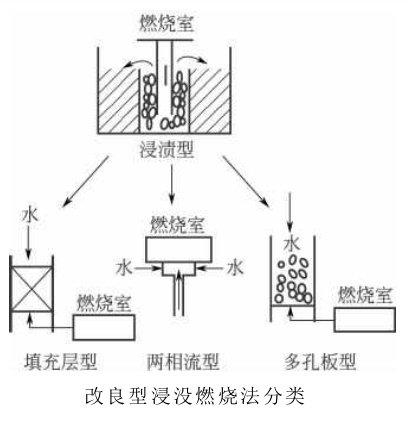

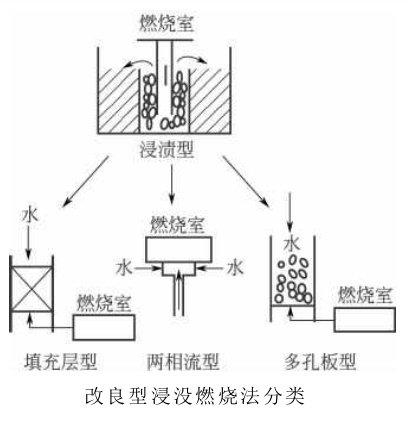

With the development and application of submerged combustion technology, in order to overcome the disadvantage of high power consumption of submerged combustion, improved submerged combustion devices have appeared one after another. Submerged combustion devices can be divided into impregnated type, packed bed type, porous plate type, and two-phase flow type. The latter three are also called improved types, as shown in the figure below.

The purpose of the early application of submerged combustion is to focus on solving the following problems when using a partitioned wall heat exchanger to heat viscous, easy to crystallize, easy to scale and highly corrosive liquids:

① The convective heat transfer coefficient of the gas is small, so that the heat transfer coefficient of the equipment is small, the heat transfer area is large, the heating equipment is large-scale, and the investment is large;

② When heating and evaporating viscous, easily crystallized and easily scaled liquids, the liquids are prone to scale and crystallize, reducing thermal efficiency and even causing accidents;

③ When heating corrosive liquid, the heat transfer surface needs to be made of high temperature resistant and corrosion resistant materials;

④ The exhaust gas temperature is high, the heat loss is large, and it is not safe;

⑤ High energy consumption per unit product.

The gas-liquid two-phase direct contact heat transfer in the submerged combustion system has the following characteristics:

One is that there is no need for fixed heat transfer surfaces necessary for partition wall heat exchangers or evaporators, so there is no crystallization, scaling and corrosion problems on the heat transfer surfaces, saving high temperature resistant and corrosion resistant materials;

The second is that the high-temperature flue gas is discharged from the liquid after bubbling. Because the gas-liquid mixing and agitation are very strong, the contact area between the gas-liquid, that is, the two-phase contact heat transfer area, is greatly increased, and the heat transfer process is strengthened. Therefore, the exhaust gas temperature Low temperature, high thermal efficiency, less energy consumption per unit product, simple equipment, and less investment.

Immersion combustion not only solves the problems of viscous heating, easy crystallization, easy scaling and strong corrosion in the partition wall heat exchanger, but also improves the energy utilization rate of the device. Therefore, its research and application have exceeded the viscous , Easy to crystallize, easy to scale and corrosive liquid heating range, and become one of the important measures for energy saving.

The measures to enhance the heat and mass transfer of submerged combustion mainly include:

① Increase the velocity of the flue gas sprayed into the liquid, increase the disturbance, and increase the heat and mass transfer coefficient;

② The gas is dispersed in the liquid with tiny bubbles to increase the gas-liquid contact area;

③ Select an appropriate immersion depth to prolong the gas-liquid contact time.

2. Submerged burner application

Immersion combustion is widely used in the heating of liquids, the heating, regeneration and concentration of various pickling liquids, the deacidification and purification of waste water, the neutralization of alkaline waste liquids, the production of inert gases and reducing gases, the gasification of liquids, cleaning Storage tanks and pipelines and other processes.

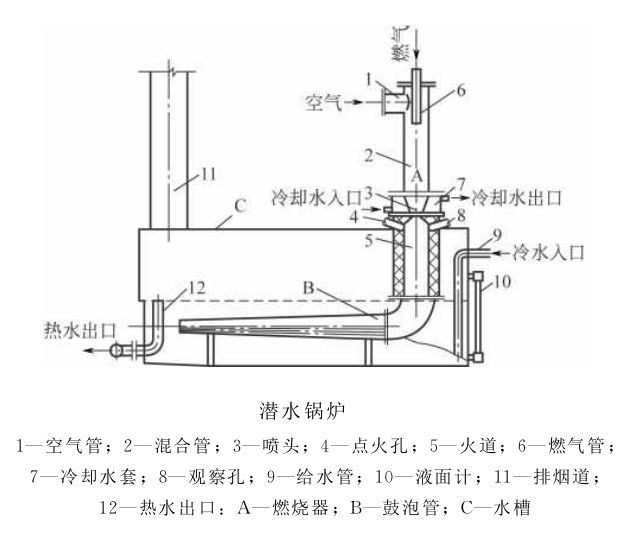

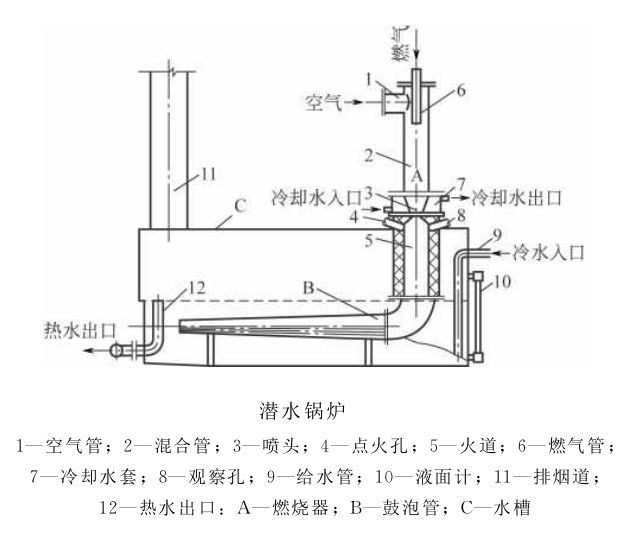

The figure below shows a submersible boiler. The combustion chamber is lined with refractory materials, and the immersion tube is a horizontal tapered bubbling tube. There are many small holes drilled in the lower half of the bubbling tube, and the high-temperature flue gas is sprayed into the liquid through the small holes to heat the liquid.

1. Working principle and characteristics of submerged burner

The immersion combustion method, also known as the liquid combustion method, is a new combustion technology. It is to fully mix gas and air, send it into the combustion chamber for complete combustion, and then spray high-temperature flue gas into the liquid to heat the liquid. Most of the combustion process of submerged combustion method belongs to complete premixed combustion, and its heat transfer process belongs to direct contact heat and mass transfer.

The earliest submerged combustion device was invented by Collier in England in 1889. Because the device does not have a special combustion chamber, it is directly sprayed into the liquid like a flame, so it is named submerged combustion (as shown in the figure below).

At present, the widely used submerged combustion device is the evaporation device shown in the figure below. Its main feature is that a combustion chamber is set on the liquid surface, which plays a role in ensuring stable flame and complete combustion.

With the development and application of submerged combustion technology, in order to overcome the disadvantage of high power consumption of submerged combustion, improved submerged combustion devices have appeared one after another. Submerged combustion devices can be divided into impregnated type, packed bed type, porous plate type, and two-phase flow type. The latter three are also called improved types, as shown in the figure below.

The purpose of the early application of submerged combustion is to focus on solving the following problems when using a partitioned wall heat exchanger to heat viscous, easy to crystallize, easy to scale and highly corrosive liquids:

① The convective heat transfer coefficient of the gas is small, so that the heat transfer coefficient of the equipment is small, the heat transfer area is large, the heating equipment is large-scale, and the investment is large;

② When heating and evaporating viscous, easily crystallized and easily scaled liquids, the liquids are prone to scale and crystallize, reducing thermal efficiency and even causing accidents;

③ When heating corrosive liquid, the heat transfer surface needs to be made of high temperature resistant and corrosion resistant materials;

④ The exhaust gas temperature is high, the heat loss is large, and it is not safe;

⑤ High energy consumption per unit product.

The gas-liquid two-phase direct contact heat transfer in the submerged combustion system has the following characteristics:

One is that there is no need for fixed heat transfer surfaces necessary for partition wall heat exchangers or evaporators, so there is no crystallization, scaling and corrosion problems on the heat transfer surfaces, saving high temperature resistant and corrosion resistant materials;

The second is that the high-temperature flue gas is discharged from the liquid after bubbling. Because the gas-liquid mixing and agitation are very strong, the contact area between the gas-liquid, that is, the two-phase contact heat transfer area, is greatly increased, and the heat transfer process is strengthened. Therefore, the exhaust gas temperature Low temperature, high thermal efficiency, less energy consumption per unit product, simple equipment, and less investment.

Immersion combustion not only solves the problems of viscous heating, easy crystallization, easy scaling and strong corrosion in the partition wall heat exchanger, but also improves the energy utilization rate of the device. Therefore, its research and application have exceeded the viscous , Easy to crystallize, easy to scale and corrosive liquid heating range, and become one of the important measures for energy saving.

The measures to enhance the heat and mass transfer of submerged combustion mainly include:

① Increase the velocity of the flue gas sprayed into the liquid, increase the disturbance, and increase the heat and mass transfer coefficient;

② The gas is dispersed in the liquid with tiny bubbles to increase the gas-liquid contact area;

③ Select an appropriate immersion depth to prolong the gas-liquid contact time.

2. Submerged burner application

Immersion combustion is widely used in the heating of liquids, the heating, regeneration and concentration of various pickling liquids, the deacidification and purification of waste water, the neutralization of alkaline waste liquids, the production of inert gases and reducing gases, the gasification of liquids, cleaning Storage tanks and pipelines and other processes.

The figure below shows a submersible boiler. The combustion chamber is lined with refractory materials, and the immersion tube is a horizontal tapered bubbling tube. There are many small holes drilled in the lower half of the bubbling tube, and the high-temperature flue gas is sprayed into the liquid through the small holes to heat the liquid.