As new enterprises enter the export market, the production structure of Riyalo Group has been consolidated. In September, the Riyadh Trade Department was established to oversee the sales of all products. Riyadh Solutions and Services are committed to fully meeting customer requirements.

The shift in production of solar panels and boilers at the Piombino (Padua) factory marks the entry of the Riyalo Group into the renewable energy sector. Starting in 2009, a production factory was established in China.

Over 500000 burners were produced and sold that year.

The expansion of the burner production center has been completed.

The combustion research and development center will be expanded to three times the original area.

Establish a new department responsible for overseeing the sales of all products. The group continues to communicate and promote, making the public aware of the purpose and organization of the Italian Riyadh Group: Riyadh Group's solutions and services are committed to fully meeting customer requirements.

In 1993, the company built a new boiler production factory; In 1997, the modern chemical plant newly built in Leniago began producing burners.

As new enterprises enter the export market, the industrial structure of Riyalo Group has been consolidated.

Focusing on core business: establishing the Riyalo burner brand.

New product development and burner production center completed

Liya Road Beijing Representative Office Established

The expansion of the combustion research and development center will double the original area. Launch Gulliver Blu Low NOx Emission Burner.

Vigorously expand overseas markets and establish overseas subsidiaries in major European countries, including the UK, Germany, France, Belgium, and Switzerland. In Italy, the company's sales underwent significant changes, with the merger of its sales network with Isothermo Riyalo (1987) and the launch of a new trademark with a red triangle and four circles, marking the company's entry into a new market area. In order to expand its market scope, the company has sponsored the Benetton Formula One racing team under the name "Benetton Riyadh" for five consecutive years. At the same time, all heating and cooling products of Riyalo Group began commercial sales. In the years after 1986, in addition to traditional burners, the company supplied approximately 140 series of products to the market.

The combustion laboratory located in Anjari, Verona, Italy was built for the research and production of high-power burners.

The group established a holding company called "OFR Officine Fratelli Riello SpA" and renamed it "RBL Riello Burners Legnago SpA". The shareholders are 10 group companies operating in Italy and overseas. Riyalo Group's industrial sector has developed strongly, continuing to invest in Italian and overseas products and sales institutions, and has developed rapidly within a decade. Meanwhile, a factory located in Mississauga, Canada was completed.

Launched the Mectron series of electronic burners from the 1980s

First burner sale in the US market.

The company became a joint-stock company of "O.F.R. Officine Fratelli Riello".

Burner sales continue to grow in Europe and Africa.

Riello Export was established in Padua, Italy to coordinate the development of overseas companies.

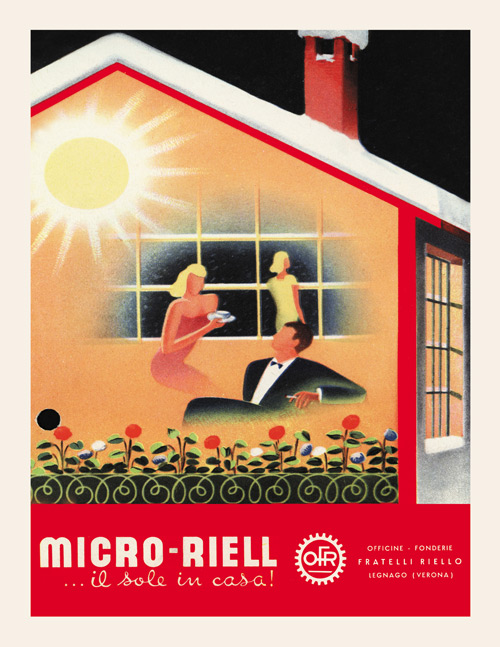

The 1960s were an important period of development for the company and for Italian society as a whole. Television advertising gradually developed, and the Rialor Group used the cartoon "Unca Dunca" to carry out a successful TV promotion, which further developed the Rialor brand.

With a major business strategy, the company has established a strong distribution network in Italy.

The special tool machine department was established to realize the automatic production of the main parts of the burner.

In addition to the production of burners, Riyadh has also introduced other products such as air conditioning equipment. Initially, these new production lines were imported from the United States, after which production began at the Riyadh plant.

Production equipment was increased to meet the demand for burners as thermal equipment.

After the Second World War, production gradually resumed, and heavy oil burners returned to the dominant position, especially the successful application of heavy oil fuel in domestic domestic and industrial thermal energy equipment.

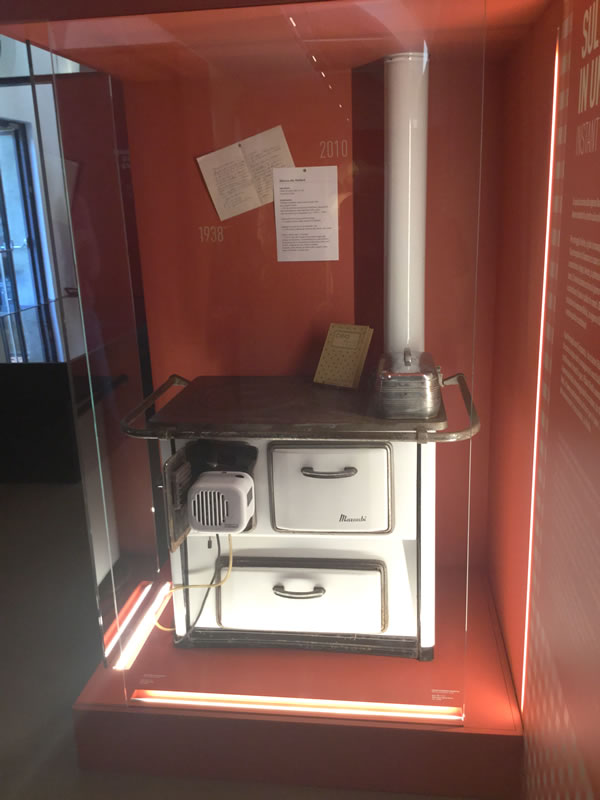

The thermal sector is in crisis and the company produces special tool machines for the domestic market.

Due to the significant reduction in available liquid fuel, the first coal-fueled automatic burner was developed and put into production.