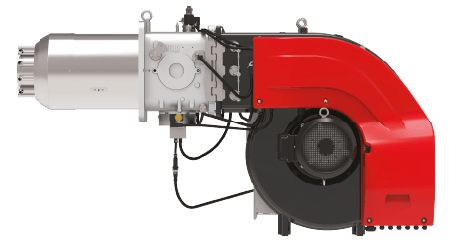

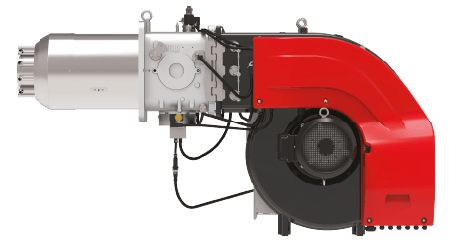

The maximum output of the RS 1000÷1200 series integrated gas burner is 11,100 kilowatts. It has been upgraded based on a new layout, created a new style, added important functions, and made the ease of use more prominent, even better than before.

This model of product is based on the traditional layout of Riello's integrated burners, adhering to common solutions for various power products, and pioneeringly introduces new concepts.

In order to maintain the reputation of Italian design on the world stage, Riello has always sought the perfect combination of design and manufacturing with innovative style since the beginning of its business development.

The new RS 1000÷1200 series of products maintains the perfect combination of performance and design, making this series of products distinctive in style.

Brand new control panel design:

Smaller size

Burners are easier to operate

more durable

Electronic components are easy to maintain

Adopt advanced combustion head design to reduce nitrogen oxide emissions

Using flue gas recirculation (FGR) technology, nitrogen oxide emissions are extremely low

Using the new LMV6 fuel-air ratio control device, the output control performance is excellent

Variable speed drive technology optimizes energy savings

Simple time-triggered flue gas recirculation control system

Adjust operating status through RWF5 PID logic regulator

RIELLO RS 1000÷1200 new LMV 6 control device

The new RS 1000÷1200 series models are equipped with a new air-fuel ratio control device LMV 6, which has excellent output control capabilities and a comfortable user interface.

The new LMV6 control unit represents decades of expertise and innovative solutions and represents the latest technological advancement in burner management systems to meet the challenges of the future.

The large display makes interaction between burner and user faster and more comfortable than before, and intuitive graphics and icons simplify system operation.

The Human Machine Interface (HMI) also improves operational safety by requiring additional confirmation of safety-relevant changes.

The guided commissioning method makes setting up the burner correctly faster, easier and therefore less expensive.

Various functions of the human-machine interface (HMI) will significantly increase work speed and greatly improve work efficiency.

Main features of RS 1000÷1200 series burner LMV6 units

Graphical Human Machine Interface (HMI

Add Chinese interface to further improve user experience

The burner program controller includes a gas valve inspection system

Three actuators feature electronic fuel-to-air ratio control

Time-triggered flue gas recirculation mode

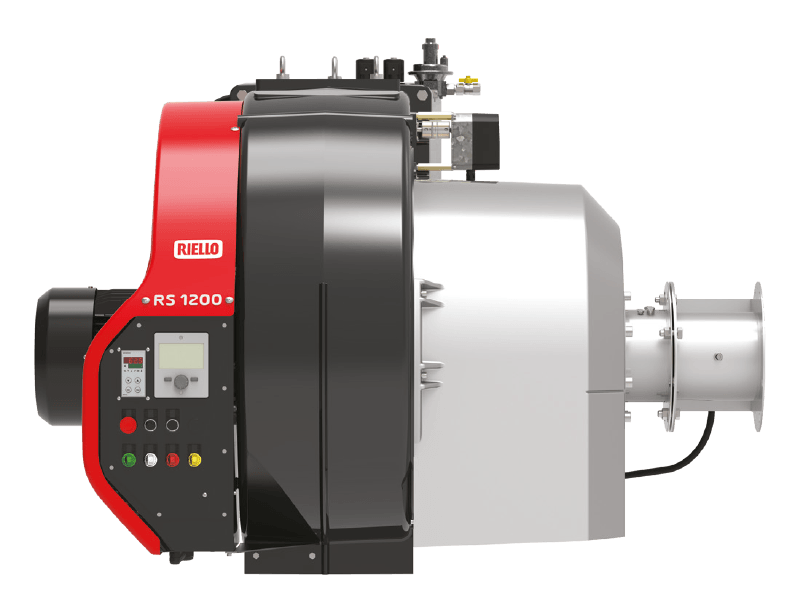

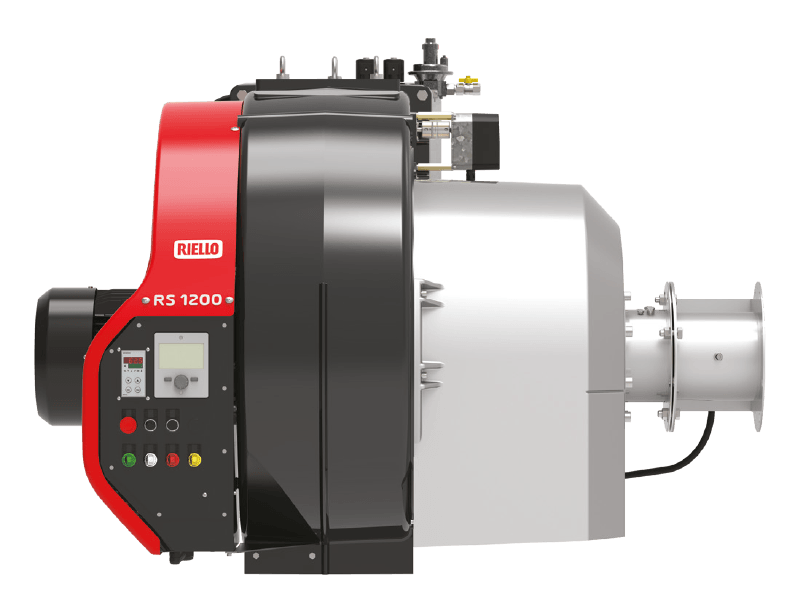

The maximum output of the RS 1000÷1200 series integrated gas burner is 11,100 kilowatts. It has been upgraded based on a new layout, created a new style, added important functions, and made the ease of use more prominent, even better than before.

This model of product is based on the traditional layout of Riello's integrated burners, adhering to common solutions for various power products, and pioneeringly introduces new concepts.

In order to maintain the reputation of Italian design on the world stage, Riello has always sought the perfect combination of design and manufacturing with innovative style since the beginning of its business development.

The new RS 1000÷1200 series of products maintains the perfect combination of performance and design, making this series of products distinctive in style.

Brand new control panel design:

Smaller size

Burners are easier to operate

more durable

Electronic components are easy to maintain

Adopt advanced combustion head design to reduce nitrogen oxide emissions

Using flue gas recirculation (FGR) technology, nitrogen oxide emissions are extremely low

Using the new LMV6 fuel-air ratio control device, the output control performance is excellent

Variable speed drive technology optimizes energy savings

Simple time-triggered flue gas recirculation control system

Adjust operating status through RWF5 PID logic regulator

RIELLO RS 1000÷1200 new LMV 6 control device

The new RS 1000÷1200 series models are equipped with a new air-fuel ratio control device LMV 6, which has excellent output control capabilities and a comfortable user interface.

The new LMV6 control unit represents decades of expertise and innovative solutions and represents the latest technological advancement in burner management systems to meet the challenges of the future.

The large display makes interaction between burner and user faster and more comfortable than before, and intuitive graphics and icons simplify system operation.

The Human Machine Interface (HMI) also improves operational safety by requiring additional confirmation of safety-relevant changes.

The guided commissioning method makes setting up the burner correctly faster, easier and therefore less expensive.

Various functions of the human-machine interface (HMI) will significantly increase work speed and greatly improve work efficiency.

Main features of RS 1000÷1200 series burner LMV6 units

Graphical Human Machine Interface (HMI

Add Chinese interface to further improve user experience

The burner program controller includes a gas valve inspection system

Three actuators feature electronic fuel-to-air ratio control

Time-triggered flue gas recirculation mode