Fossil fuel burners are often used as the primary medium for delivering energy to industrial furnaces and ovens.

The growing focus on reducing energy costs has led manufacturers to research and develop new burner design techniques, and significant gains in efficiency gains have been made over the years. Burner management and control systems must be equally adaptable.

Riello offers you efficient and functional control technology that reduces operating costs while providing adequate resources for flexibility in plant management and control. Burner combustion usually includes one of the following schemes or a combination of multiple schemes

excess air conditioning

oxygen device

burner modulation

Air/Fuel Cross Limit

overall thermal control

excess air conditioning

In reality, gas, oil, coal, and other systems do not achieve perfect fuel and air mixing, even under optimal conditions. Also, thorough mixing can be a lengthy process. Figure 1 shows that a reasonable amount of excess air needs to be maintained in order to ensure complete combustion and minimize heat loss.

Excess air conditioning can obtain:

Better Furnace Thermal Conductivity

"Early warning" of fuel and gas problems (excess air is vented from the most efficient zone)

massive fuel savings

oxygen device

When it is possible to measure the oxygen in the fuel gas, the combustion control mechanism can be greatly improved by adding an oxygen device control module (since the percentage of oxygen in the fuel is closely related to the amount of excess air), allowing:

Tighter control of excess air at the oxygen set point for greater efficiency

Faster return to set point after a disturbance

Tighter controls on fuel emissions

Compliance with emission standards

Easier to bind carbon monoxide or reduce smoke

burner modulation

Modulation control is a fundamental improvement in combustion control. A controller monitoring the furnace atmosphere generates a continuous demand signal.

The reduction in temperature increases the flame intensity. The advantages of introducing burner modulation in combustion control include:

Fuel and air can be continuously proportioned according to combustion requirements

Can keep the furnace temperature error smaller

Improve Furnace Efficiency

Lower weighted average fuel gas temperature

Air/Fuel Cross Limit

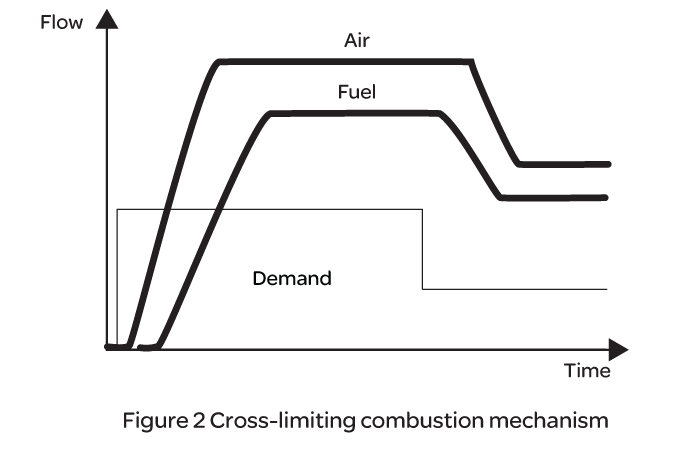

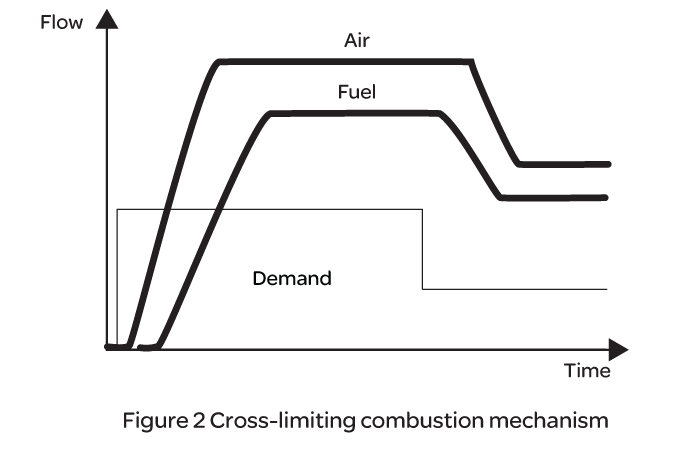

The cross-limiting of the combustion control strategy ensures that no dangerous air-fuel ratios occur during the combustion process. This is achieved by always increasing the air flow before allowing the fuel flow to increase (as shown in Figure 2), or decreasing the fuel flow before allowing the air flow to decrease.

Cross limit combustion control is highly effective and also conveniently provides the following functions:

optimize fuel consumption

Reduces explosion hazards and provides safer working conditions

Quickly adapt to changes in fuel and air supply

Meet the factory's demand for steam

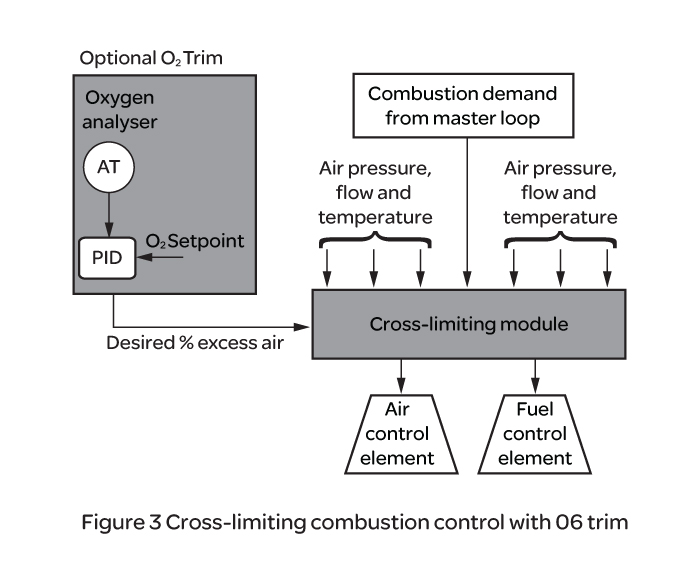

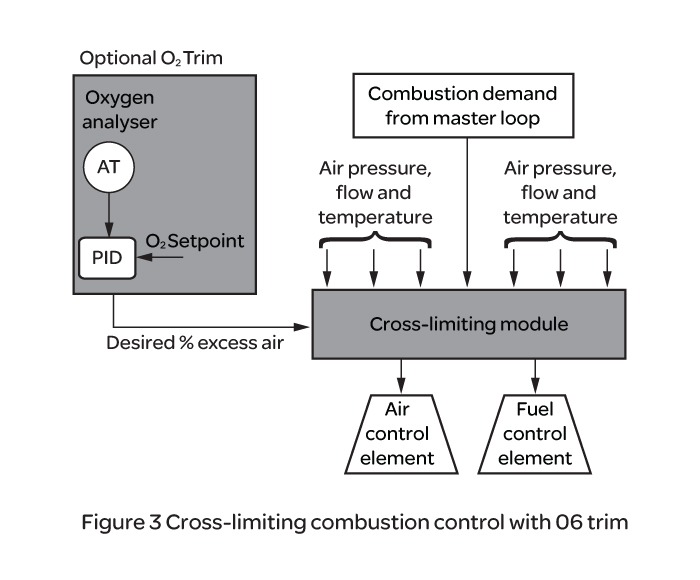

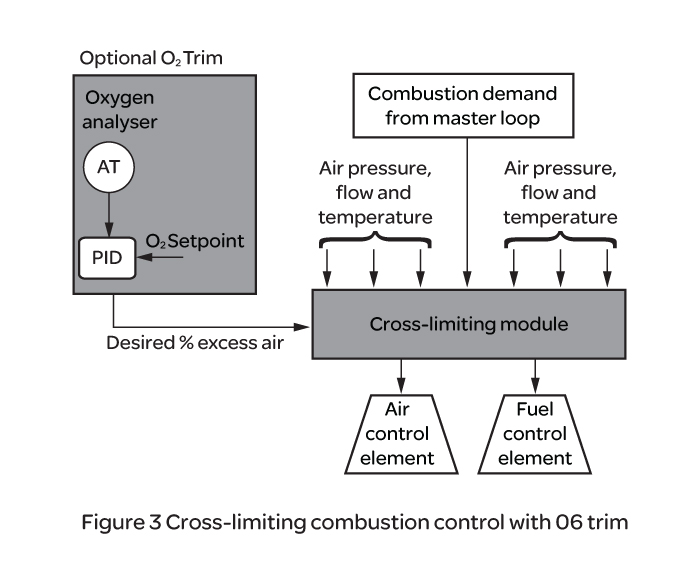

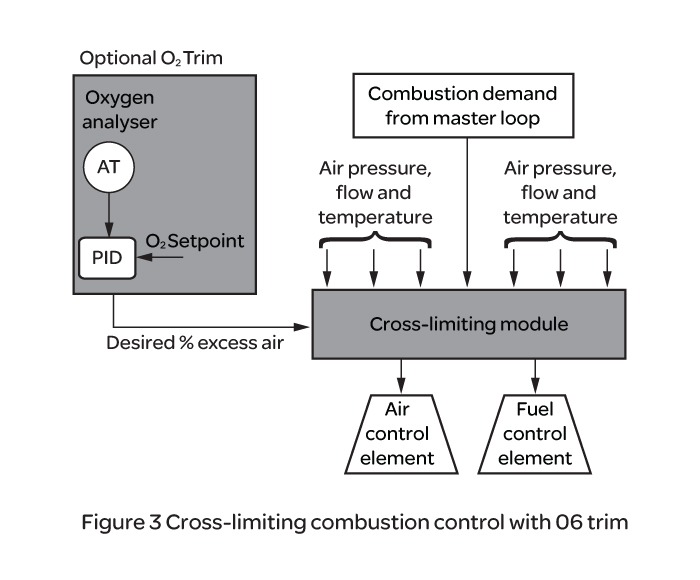

Figure 3 is a simplified control block diagram of a cross-limited combustion circuit. Simultaneous combustion of multiple fuels can also be easily accommodated in this scheme.

Enhanced Cross Limit

The dual crossover limited combustion control is an enhancement of the above. It does this by adding dynamic limits to the air and fuel set points. This keeps the actual air-fuel ratio within preset ranges during and after the air and fuel switchover. This approach prevents the demand signal from reducing the air-fuel ratio too much, thereby reducing heat loss.

Tight Coupling Control

Most heat treatment processes require precise control of the material temperature. Sensible cascade control of furnaces can be easily achieved with the advent of fast acting burners and burner control systems.

In this mode, the burner is under tight temperature control with sensors tightly coupled to the delivered energy. A tightly coupled slave loop responds to the needs of the master loop (where the sensor is inside the workpiece). In this way, the furnace can be fully optimized to meet burner power and workpiece requirements, maximize efficiency, and secure the heat treatment process.

Fossil fuel burners are often used as the primary medium for delivering energy to industrial furnaces and ovens.

The growing focus on reducing energy costs has led manufacturers to research and develop new burner design techniques, and significant gains in efficiency gains have been made over the years. Burner management and control systems must be equally adaptable.

Riello offers you efficient and functional control technology that reduces operating costs while providing adequate resources for flexibility in plant management and control. Burner combustion usually includes one of the following schemes or a combination of multiple schemes

excess air conditioning

oxygen device

burner modulation

Air/Fuel Cross Limit

overall thermal control

excess air conditioning

In reality, gas, oil, coal, and other systems do not achieve perfect fuel and air mixing, even under optimal conditions. Also, thorough mixing can be a lengthy process. Figure 1 shows that a reasonable amount of excess air needs to be maintained in order to ensure complete combustion and minimize heat loss.

Excess air conditioning can obtain:

Better Furnace Thermal Conductivity

"Early warning" of fuel and gas problems (excess air is vented from the most efficient zone)

massive fuel savings

oxygen device

When it is possible to measure the oxygen in the fuel gas, the combustion control mechanism can be greatly improved by adding an oxygen device control module (since the percentage of oxygen in the fuel is closely related to the amount of excess air), allowing:

Tighter control of excess air at the oxygen set point for greater efficiency

Faster return to set point after a disturbance

Tighter controls on fuel emissions

Compliance with emission standards

Easier to bind carbon monoxide or reduce smoke

burner modulation

Modulation control is a fundamental improvement in combustion control. A controller monitoring the furnace atmosphere generates a continuous demand signal.

The reduction in temperature increases the flame intensity. The advantages of introducing burner modulation in combustion control include:

Fuel and air can be continuously proportioned according to combustion requirements

Can keep the furnace temperature error smaller

Improve Furnace Efficiency

Lower weighted average fuel gas temperature

Air/Fuel Cross Limit

The cross-limiting of the combustion control strategy ensures that no dangerous air-fuel ratios occur during the combustion process. This is achieved by always increasing the air flow before allowing the fuel flow to increase (as shown in Figure 2), or decreasing the fuel flow before allowing the air flow to decrease.

Cross limit combustion control is highly effective and also conveniently provides the following functions:

optimize fuel consumption

Reduces explosion hazards and provides safer working conditions

Quickly adapt to changes in fuel and air supply

Meet the factory's demand for steam

Figure 3 is a simplified control block diagram of a cross-limited combustion circuit. Simultaneous combustion of multiple fuels can also be easily accommodated in this scheme.

Enhanced Cross Limit

The dual crossover limited combustion control is an enhancement of the above. It does this by adding dynamic limits to the air and fuel set points. This keeps the actual air-fuel ratio within preset ranges during and after the air and fuel switchover. This approach prevents the demand signal from reducing the air-fuel ratio too much, thereby reducing heat loss.

Tight Coupling Control

Most heat treatment processes require precise control of the material temperature. Sensible cascade control of furnaces can be easily achieved with the advent of fast acting burners and burner control systems.

In this mode, the burner is under tight temperature control with sensors tightly coupled to the delivered energy. A tightly coupled slave loop responds to the needs of the master loop (where the sensor is inside the workpiece). In this way, the furnace can be fully optimized to meet burner power and workpiece requirements, maximize efficiency, and secure the heat treatment process.